Reviewing Electrical Compliance Testing Requirements for New Installations

Electrical compliance testing is a crucial step in ensuring that all newly installed electrical systems meet safety and operational standards. This not only prevents accidents but also guarantees that installations meet legal requirements. Let's explore the essentials of electrical compliance testing, focusing on the key steps, types of tests, and industry standards that ensure every setup is safe and compliant.

What is Electrical Compliance Testing?

Electrical compliance testing refers to a series of tests and inspections conducted on new or existing electrical installations to confirm that they meet regulatory standards. These tests are designed to evaluate whether the installation operates safely and effectively, preventing electrical faults or hazards. Compliance testing covers various components, including wiring, circuits, and electrical appliances.

Why Electrical Compliance Testing is Essential

Electrical compliance testing isn’t just about following rules. It plays a critical role in:

- Ensuring Safety: Testing protects individuals from potential hazards like electric shocks, fires, and short circuits.

- Preventing Future Hazards: A compliant system is less likely to experience faults, reducing maintenance costs.

- Meeting Legal Requirements: Compliance ensures adherence to standards set by regulatory bodies, avoiding penalties and liabilities.

Types of Electrical Compliance Tests

Compliance testing includes several types, each focusing on a particular aspect of the installation:

- Installation Testing: Performed after a new installation to ensure all components are safe and functional.

- Periodic Testing: Regular tests to verify ongoing compliance.

- Portable Appliance Testing (PAT): Tests portable electrical appliances to ensure they’re safe for use.

Regulatory Standards for Electrical Compliance

Regulations vary by country, but several bodies set standards to ensure safety and quality in electrical installations. Common regulatory bodies include:

- NEC (National Electrical Code) in the United States

- BS 7671 standards in the UK

- IEC Standards for international compliance

Each standard outlines specific requirements that installations must meet to pass compliance testing.

Key Requirements for New Installations

New electrical installations must adhere to stringent guidelines before they can be considered compliant. Some critical requirements include:

- Inspection Guidelines: A thorough inspection ensures all components are properly installed.

- Documentation: Detailed records of the installation and testing process.

- Certification: Certification from a licensed professional confirms compliance.

Common Tests for New Installations

During compliance testing, inspectors typically conduct several tests:

- Insulation Resistance Testing: Checks the quality of insulation to prevent leaks or faults.

- Earth Continuity Testing: Verifies that all metal parts are grounded to prevent electric shocks.

- Polarity Testing: Ensures that live and neutral wires are correctly placed.

- RCD Testing: Tests the Residual Current Device (RCD) to confirm it can detect and respond to fault currents.

Inspection Process Overview

The inspection process involves several steps to ensure that installations meet safety standards. Here's a quick rundown:

- Visual Inspection: Initial check to ensure proper installation of visible components.

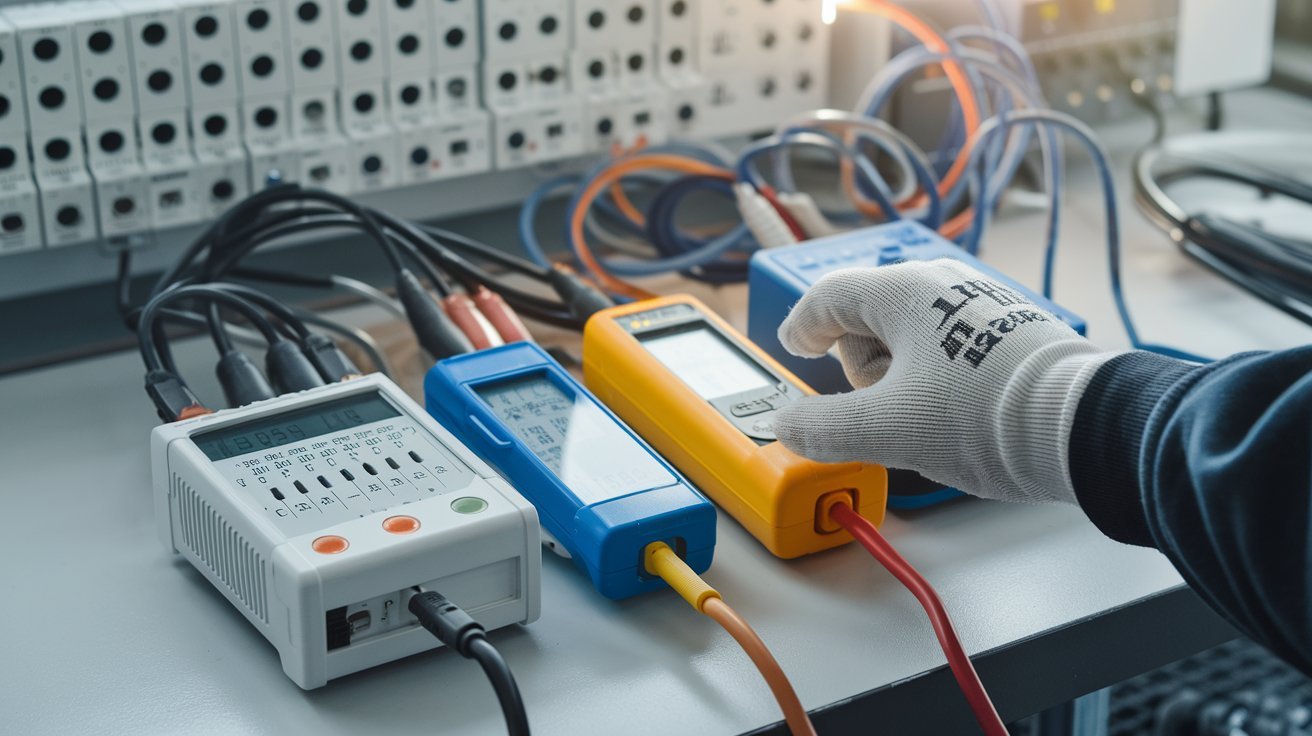

- Testing Equipment Setup: Preparing tools like insulation testers and multimeters.

- Conducting Tests: Performing tests such as earth continuity, polarity, and insulation resistance.

- Documentation: Recording results for each test performed.

Who Can Perform Electrical Compliance Testing?

Compliance testing should only be conducted by certified professionals who possess the qualifications to handle complex electrical systems. Hiring a licensed technician ensures accuracy and adherence to legal requirements, providing peace of mind for property owners.

Best Practices for Meeting Compliance Standards

Meeting compliance standards can be challenging, but following these practices helps maintain safety and efficiency:

- Stay Up-to-Date on Regulations: Standards change, so it’s important to stay informed.

- Conduct Regular Inspections: Avoid issues by performing periodic tests.

- Use Certified Tools and Equipment: Accurate equipment leads to reliable test results.

Documentation and Reporting

Accurate documentation of test results is essential for compliance. Reports should include details of each test, findings, and corrective actions taken, if any. This record is valuable for future inspections and proves compliance to regulatory bodies.

Electrical Compliance Testing in Different Environments

Compliance requirements may vary based on the setting:

- Residential Installations: Safety standards focus on protecting inhabitants from shocks and fires.

- Commercial and Industrial Environments: Often stricter due to higher power demands and risk factors.

Maintaining Compliance Post-Installation

After a new installation is certified, periodic testing is crucial for continued compliance. Regular maintenance and inspections can help identify issues early, ensuring the electrical system remains safe and operational.

Cost of Electrical Compliance Testing

The cost of compliance testing varies based on factors such as installation size, location, and the complexity of the system. While it may seem costly upfront, compliance testing can prevent costly repairs and hazards down the line.

Conclusion

Electrical compliance testing is essential for ensuring the safety, efficiency, and legality of new installations. By understanding the requirements and following best practices, property owners and electricians can protect both lives and assets while staying compliant. Regular inspections and adherence to regulations are the keys to maintaining a safe and efficient electrical system.

FAQs

What is the role of an electrical compliance certificate?

An electrical compliance certificate verifies that an installation meets safety standards, serving as proof of compliance.

How often should compliance testing be performed on new installations?

Testing is recommended at least once after installation and periodically afterward, depending on local regulations.

Can I perform compliance testing on my own?

Only certified professionals should perform compliance testing to ensure accuracy and adherence to standards.

What happens if a new installation fails compliance testing?

If an installation fails, the inspector will provide a list of necessary improvements. These must be addressed before the installation can pass.

Why is documentation so important in compliance testing?

Documentation provides a record of safety compliance, which is critical for future inspections, insurance claims, and regulatory reviews.