Back in the height of the pandemic, "sanitize everything" was practically the world's slogan.

Amid that paranoia, a janitor named Kyieme noticed something strange: people—especially women—were bringing their drinks into public restrooms to avoid tampering.

But inside? There was nowhere clean to put them.

That's when the spark hit.

"What if you could safely lock your drink away—and sanitize it—while you were gone?"

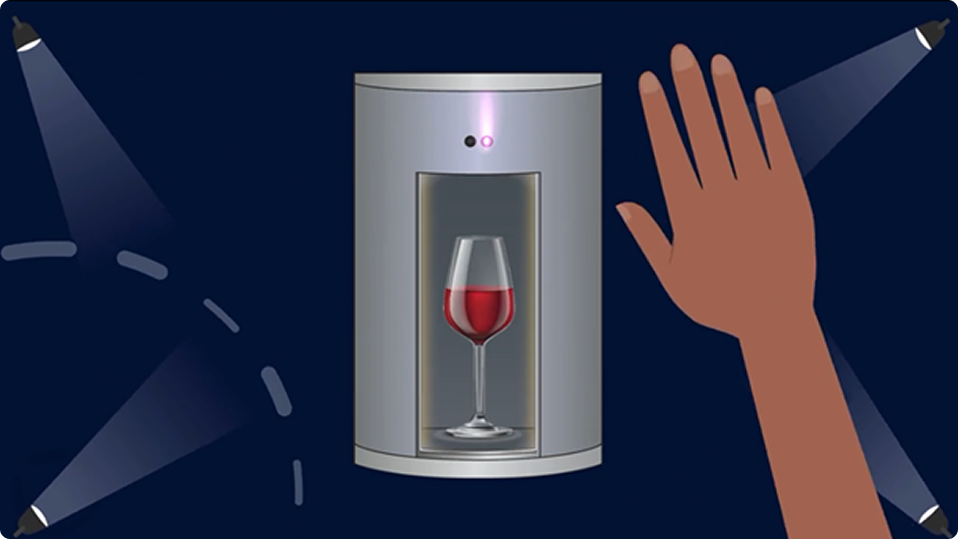

The UV Drink Locker (UVDL) was born: a small, hygienic locker that uses UVC light to sterilize your drink in 30 seconds flat.