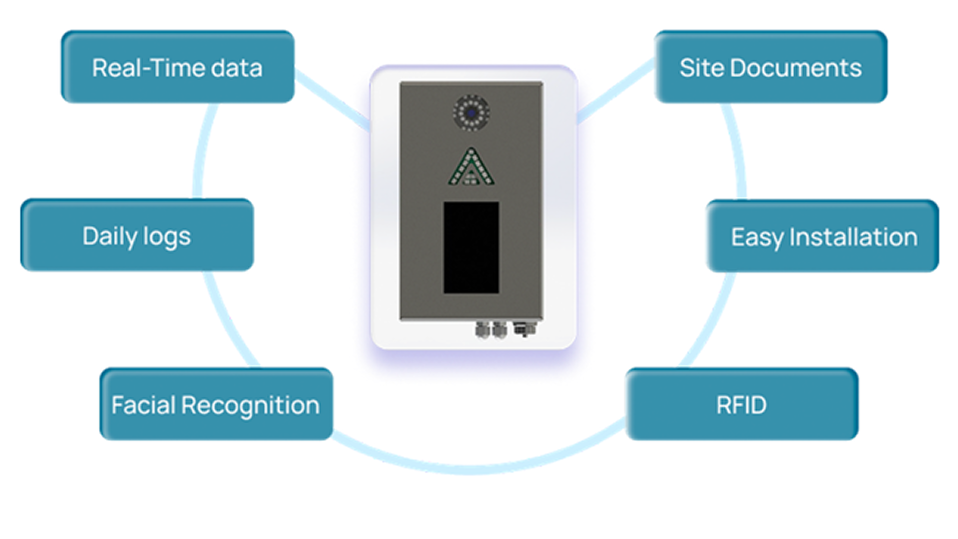

Turnstiles are deceptively complex. They handle constant torque loads, electrical surges, and timing precision that has to sync with external systems — card readers, gates, and foot traffic sensors.

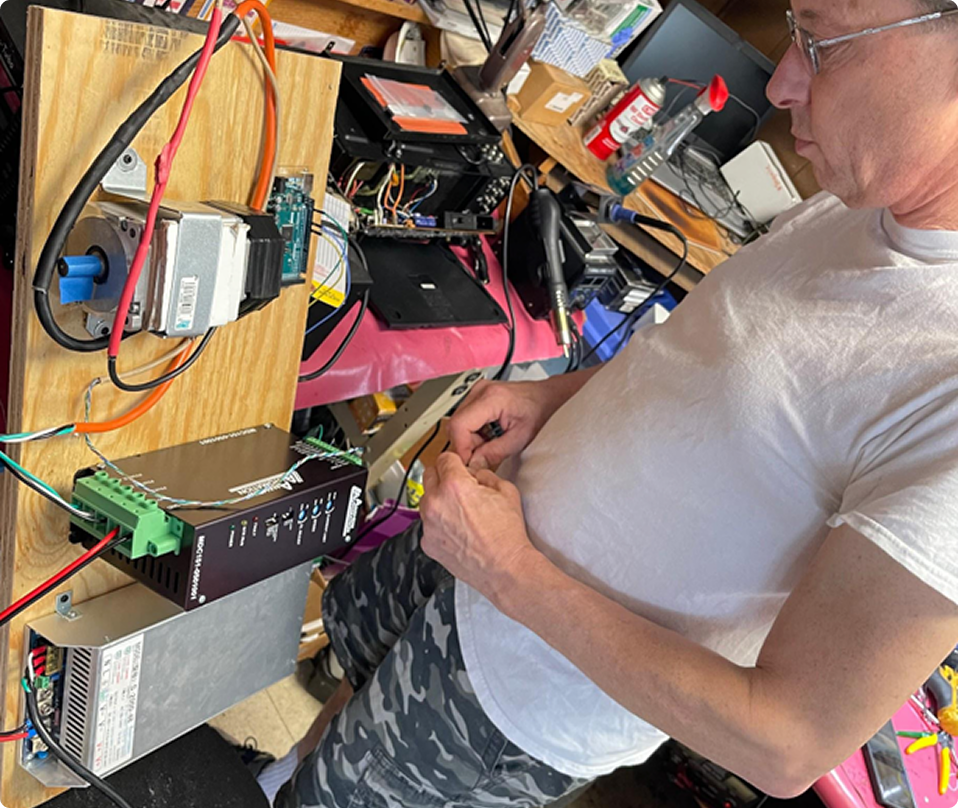

Most ECUs fail because they're designed like consumer electronics, not industrial devices.

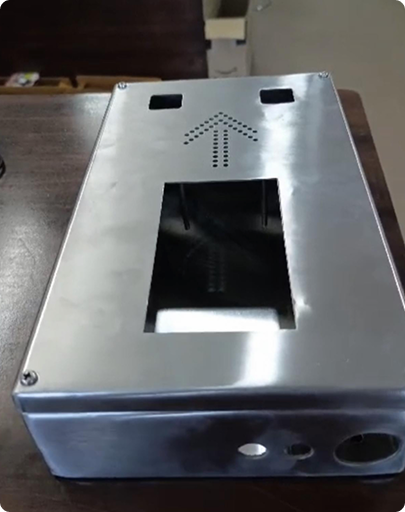

We needed something field-serviceable, modular, and future-proof.

If a board failed, maintenance should take minutes — not shutdowns.